Installation Instructions

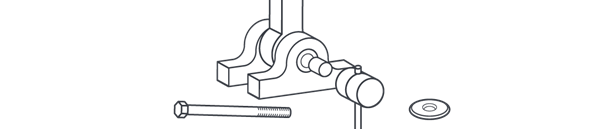

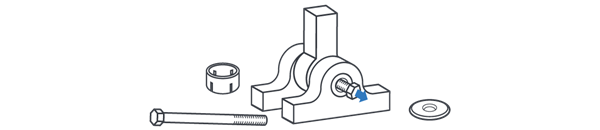

Straight Pin, Through Bolt

5.1

Following these instructions will ensure that the Expander System is installed correctly and the pivot life is prolonged.

Congratulations! You have purchased a custom engineered solution to the pivot wear problem on your machine. Contact your dealer or Expander before proceeding if you have any questions.

Expander System pivot pin comes with a warranty against lug wear of 10 years / 10 000 hours in operation (whichever comes first) from the date of purchase.

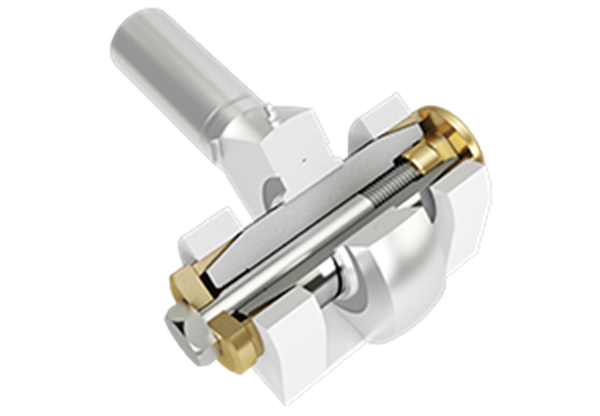

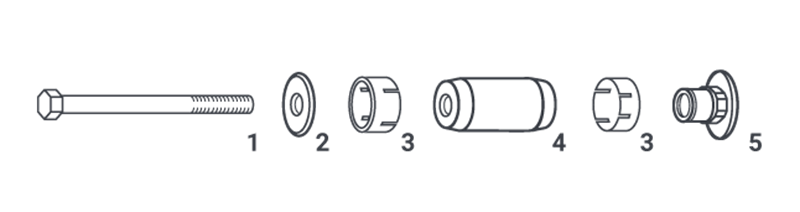

1 Bolt. 2 Washer. 3 Sleeve. 4 Axle (Pin). 5 Expander flat-headed nut for internal hexagon.

Preparation

拆除任何轴衬以避免日后轴衬和安装凸耳间出现磨损。

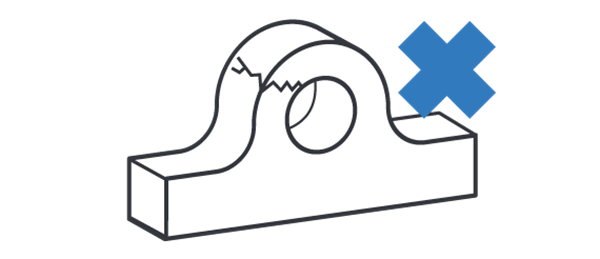

如安装前出现的裂缝或凸耳弯曲,请先对结构损伤部分 进行修复。

消除沉头孔内的不规则部分。

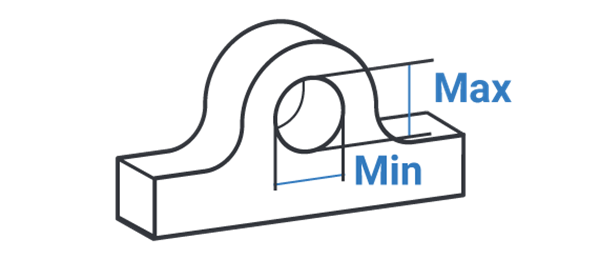

套筒的磨损凸耳最大与最小直径差必须小于 06” (1.5mm),以进行正确配合。

ATTENTION! If the worn lugs diameter at any point is 2 mm (.080”) or more over original lug diameter contact your dealer or Expander System. You will need oversized sleeves.

Installation

用现有的润滑油对套筒和轴进行润 滑,最好用石墨润滑脂。请勿对螺纹 进行润滑!

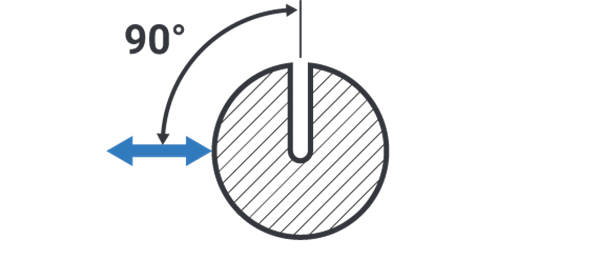

注意! 如果适用:使润滑油出口 与作用力方向呈 90 度角,以最 小化出口处的应力集中。

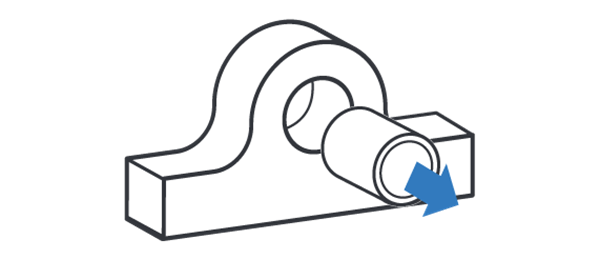

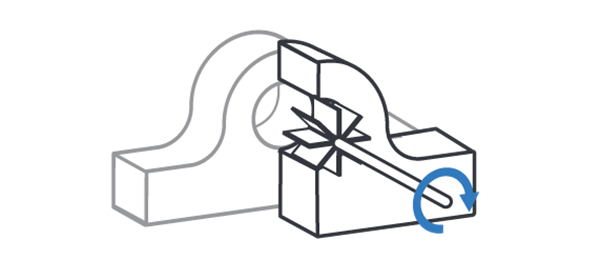

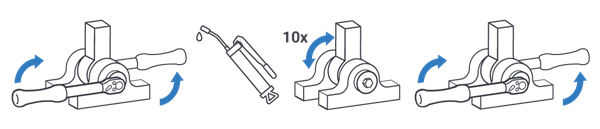

Install the Expander System loosely assembled. Position it in the bores and tighten the fastener. Hold the washer with a plier to prevent the axle from turning. Torque as specified.

Torque recommendations

六角螺栓和安装工具螺栓

扭矩 M12-M24 ± 10%, M30... +30/-0%

| M12 | M14 | M16 | M20 | M24 | M30 | M36 | M42 | |

| Nm | 70 | 115 | 175 | 350 | 500 | 600 | 700 | 900 |

| lb-ft | 52 | 85 | 129 | 258 | 369 | 443 | 516 | 664 |

六角螺母:标准高度

扭矩 M12-M24 ± 10%, M30... +30/-0%

| M12 | M14 | M16 | M20 | M24 | M30 | M36 | M42 | |

| Nm | 65 | 115 | 175 | 250 | 350 | 500 | 600 | 700 |

| lb-ft | 48 | 85 | 129 | 184 | 258 | 369 | 443 | 516 |

六角螺母:低高度

扭矩 M12-M24 ± 10%, M30... +30/-0%

| M12 | - | M16 | M20 | M24 | M30 | - | - | |

| Nm | 60 | - | 125 | 200 | 275 | 350 | - | - |

| lb-ft | 44 | - | 92 | 148 | 203 | 258 | - | - |

扳手螺母

所有扭矩 ± 10%

| M17 | M25 | M35 | M45 | M55 | M65 | M75 | M85 | |

| Nm | 50 | 120 | 250 | 500 | 600 | 700 | 800 | 900 |

| lb-ft | 37 | 89 | 184 | 369 | 443 | 516 | 590 | 664 |

Final Check

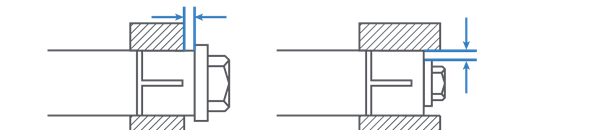

施加初始转矩后,在最大范围内移动机器数次并重新检查转 矩。

检查张力垫圈和凸耳之间的最小距离是否为 0.5 mm。 注意!如果张力垫圈与凸耳接触,请联系您的经销商或 注意! 如果张力垫圈与凸耳部分直接接触了,请联系我 们。

Dismounting

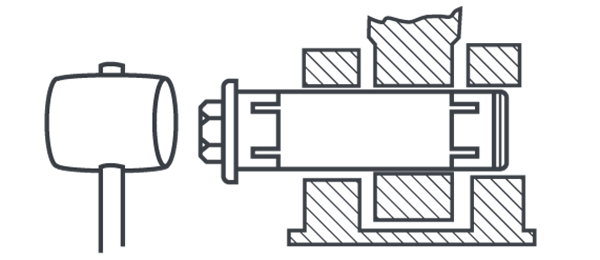

Dismount bolt and washer. Tap the axle until the tension on the sleeves is released (use a piece of pipe between the axle and the mallet/hammer not to damage the threads). Remove the sleeve with a plier.

Mount a short bolt and remove the axle using a sliding hammer, puller or similar. Bolt is normally fine pitch and sold by your dealer.