Installation Instructions

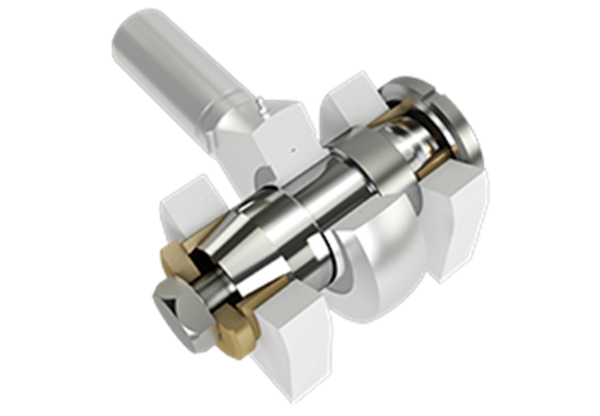

Stepped Pin, Spanner Nut Secured

5.4

Following these instructions will ensure that the Expander System is installed correctly and the pivot life is prolonged.

Congratulations! You have purchased a custom engineered solution to the pivot wear problem on your machine. Contact your dealer or Expander before proceeding if you have any questions.

Expander System pivot pin comes with a warranty against lug wear of 10 years / 10 000 hours in operation (whichever comes first) from the date of purchase.

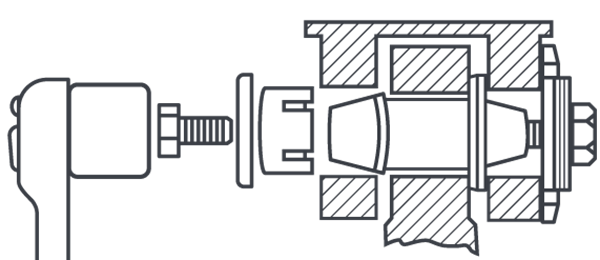

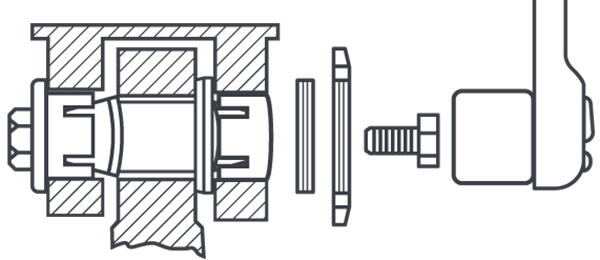

The picture shows a female axle, but the principle is the same for other designs.

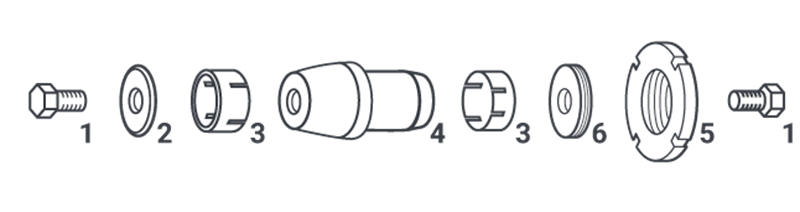

1 Bolt. 2 Washer. 3 Sleeve. 4 Axle (Pin). 5 Securing spanner nut. 6 Threaded washer.

Preparation

拆除任何轴衬以避免日后轴衬和安装凸耳间出现磨损。

如安装前出现的裂缝或凸耳弯曲,请先对结构损伤部分 进行修复。

消除沉头孔内的不规则部分。

套筒的磨损凸耳最大与最小直径差必须小于 06” (1.5mm),以进行正确配合。

ATTENTION! If the worn lugs diameter at any point is 2 mm (.080”) or more over original lug diameter contact your dealer or Expander System. You will need oversized sleeves.

Installation

用现有的润滑油对套筒和轴进行润 滑,最好用石墨润滑脂。请勿对螺纹 进行润滑!

注意! 如果适用:使润滑油出口 与作用力方向呈 90 度角,以最 小化出口处的应力集中。

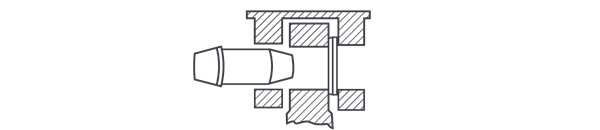

The spacer is always positioned on the opposite side of the stepped part of the axle. If the pivot already has a spacer, leave it in its position. If the Expander System includes a spacer, place it between the inner sphere of the bearing and the lug ear, with the bevel facing the bearing.

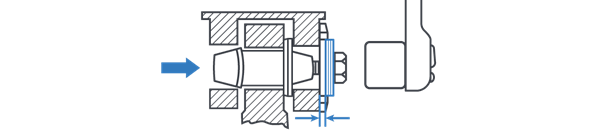

Insert the axle. Install securing spanner nut and threaded washer on the side with small axle diameter. Position to achieve a gap between the threaded washer and the lug. Mount and tighten the fastener until the axial play is eliminated.

Install sleeve, washer and fastener on the side with large axle diameter. Tighten the fastener with recommended torque.

Remove securing spanner nut and threaded washer. Install sleeve. Reinstall securing spanner nut, threaded washer and fastener. Keep the securing spanner nut loose and tighten the fastener with recommended torque. Finally tighten the securing spanner nut against the lug.

Torque recommendations

六角螺栓和安装工具螺栓

扭矩 M12-M24 ± 10%, M30... +30/-0%

| M12 | M14 | M16 | M20 | M24 | M30 | M36 | M42 | |

| Nm | 70 | 115 | 175 | 350 | 500 | 600 | 700 | 900 |

| lb-ft | 52 | 85 | 129 | 258 | 369 | 443 | 516 | 664 |

六角螺母:标准高度

扭矩 M12-M24 ± 10%, M30... +30/-0%

| M12 | M14 | M16 | M20 | M24 | M30 | M36 | M42 | |

| Nm | 65 | 115 | 175 | 250 | 350 | 500 | 600 | 700 |

| lb-ft | 48 | 85 | 129 | 184 | 258 | 369 | 443 | 516 |

六角螺母:低高度

扭矩 M12-M24 ± 10%, M30... +30/-0%

| M12 | - | M16 | M20 | M24 | M30 | - | - | |

| Nm | 60 | - | 125 | 200 | 275 | 350 | - | - |

| lb-ft | 44 | - | 92 | 148 | 203 | 258 | - | - |

扳手螺母

所有扭矩 ± 10%

| M17 | M25 | M35 | M45 | M55 | M65 | M75 | M85 | |

| Nm | 50 | 120 | 250 | 500 | 600 | 700 | 800 | 900 |

| lb-ft | 37 | 89 | 184 | 369 | 443 | 516 | 590 | 664 |

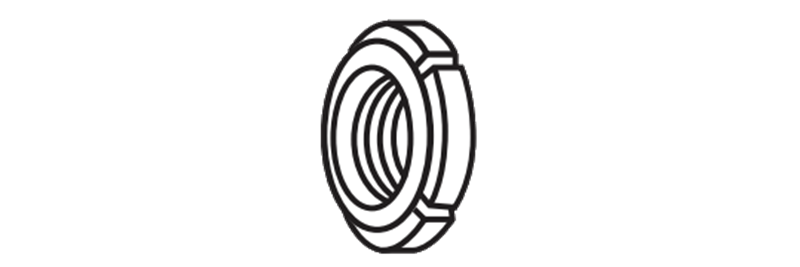

Securing Spanner Nut

Max Torque

| ....M100 | M100.... | - | - | - | - | - | - | |

| Nm | 50 | 80 | - | - | - | - | - | - |

| lb-ft | 37 | 59 | - | - | - | - | - | - |

Final Check

After initial torque, grease the pivot (if applicable), move the machine through full range of motion several times and recheck the torque. Check the torque after 10 hours, 40 hours and at regular service intervals to ensure proper seating of the sleeves.

检查张力垫圈和凸耳之间的最小距离是否为 0.5 mm。 注意!如果张力垫圈与凸耳接触,请联系您的经销商或 注意! 如果张力垫圈与凸耳部分直接接触了,请联系我 们。